Geothermal system monitoring and analysis

| Year: | 2019-2021 |

| Client: | Two geothermal Operators |

| Locatie: | Multiple locations in The Netherlands |

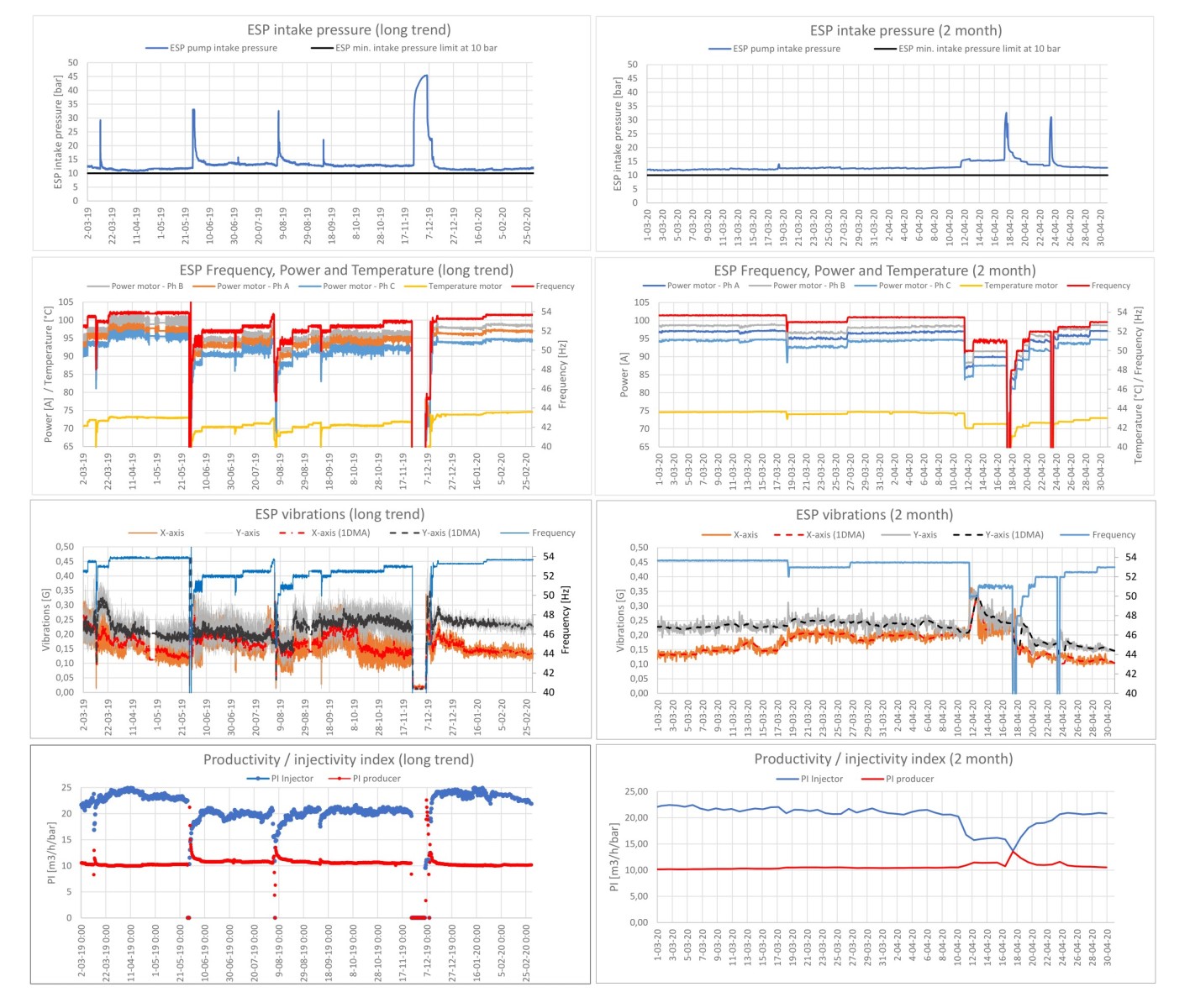

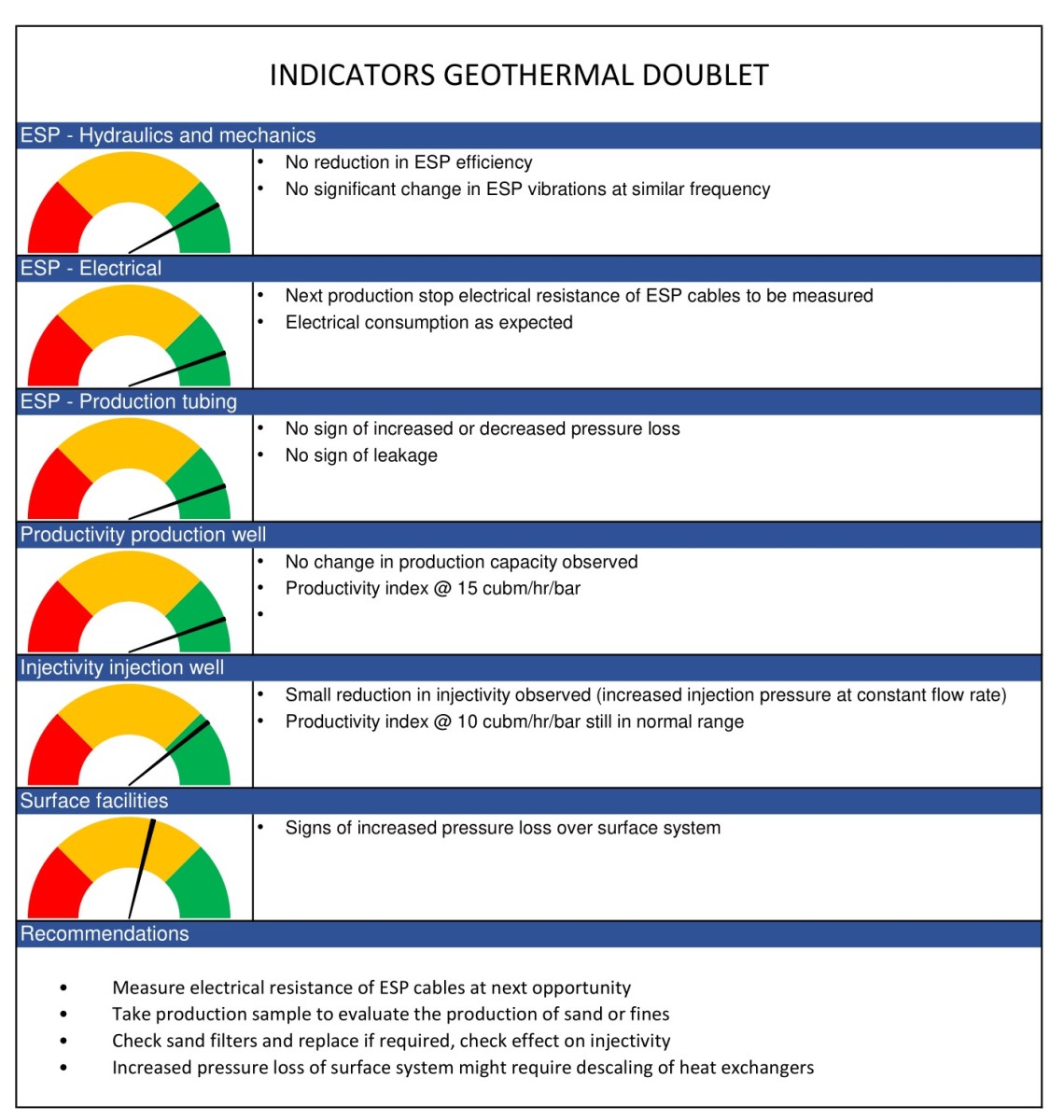

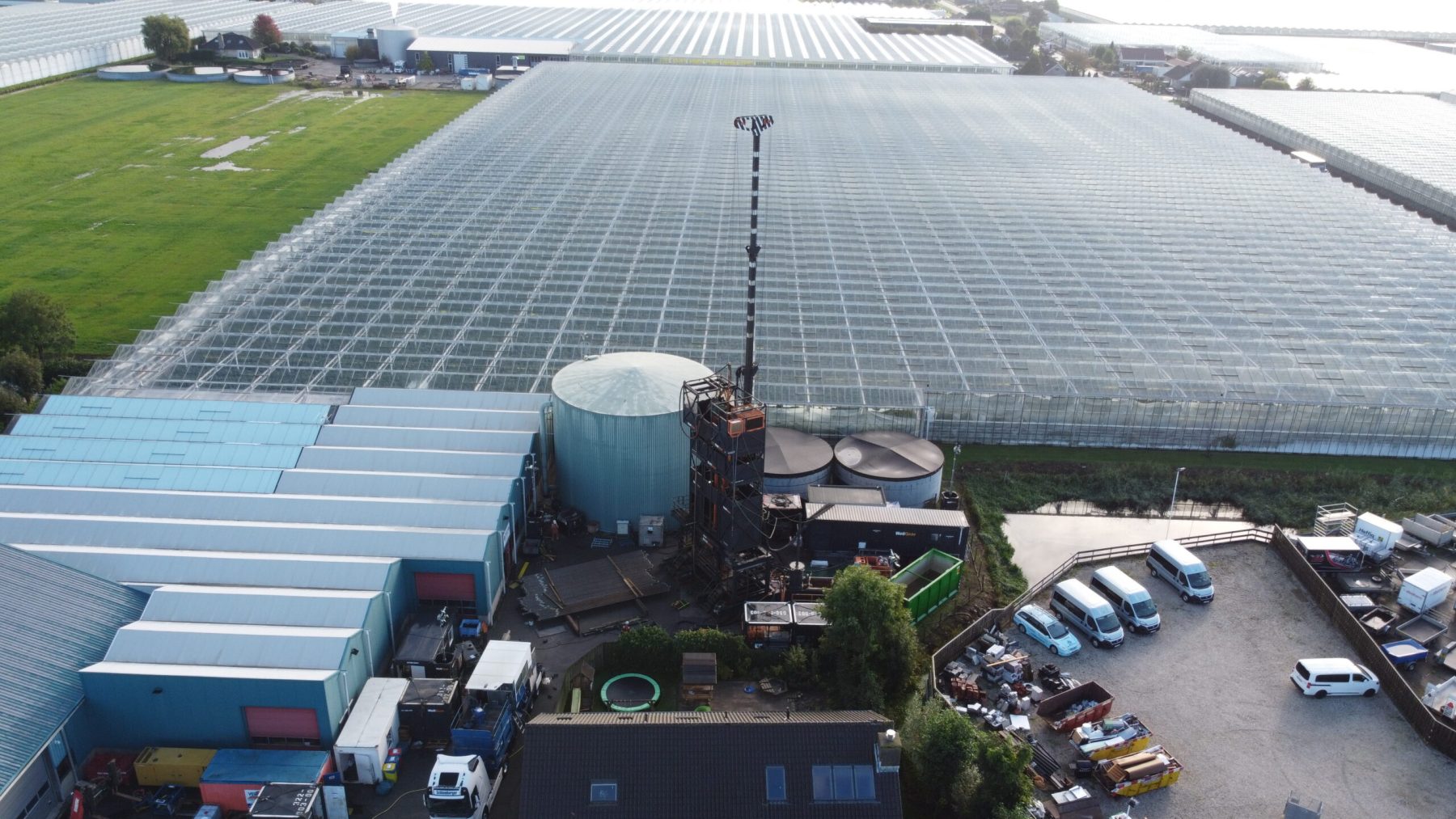

| Description: | The Geothermal Service Team has developed a monitoring system where all available data from the ESP sensors and sensors at surface are combined and translated into graphs and trendlines. These are then analyzed by a team every month (or sooner if there is an indication of something not well), consisting of a reservoir engineer, well engineer and an ESP specialist. The results of the analysis are shown as a KPI dashboard. The advantage of this system is that it bundles all available data which allows to study not only ESP but also injection / production reservoir performance and complete system behavior. |

| Challenges: | The data files can be fragmented, making data collection a time-consuming task. A solution was engineered to fully automate data capturing, which will reduce time consumption dramatically. |

| Benefits: | Using the data it was highlighted at one doublet that bio-fouling is probably taking place, reducing injectivity very gradually. This allows engineering a solution before it becomes a major problem. |

Second partial abandonment using PWC technique

| Year: | 2022 |

| Client: | Geothermal Operator |

| Location: | The Netherlands |

| Description: | The deep part of a second geothermal producer well was successfully abandoned using PWC technique. |

| Challenges: | Despite the again very tight location the job was completed successfully and as per plan. |

Partial abandonment using PWC technique

| Year: | 2021 |

| Client: | Geothermal Operator |

| Location: | The Netherlands |

| Description: | A cement plug was successfully placed in a geothermal producer well to reinstate the sealing functionality of a caprock formation above the reservoir. The casing at the plug depth was not cemented. To place cement against the formation a PWC (Perforate, Wash, Cement) technique was used: the casing is perforated over 50m, the annular space is cleaned out through jetting and circulating, after that the cement is pumped and jetted into place, both inside and outside the casing. |

| Challenges: | Despite the very tight location the job was completed successfully and as per plan. |

Concept designs for the Pimp de Put programme

| Year: | 2020 |

| Client: | Multiple clients in The Netherlands |

| Location: | Multiple locations in The Netherlands |

| Description: | Pimp the Put is the working name for a programme created by stakeholders to improve the lifetime of existing geothermal wells in the Netherlands. It usually involves the installation of a tie-back liner to the top of the reservoir liner, creating an additional corrosion barrier and a monitorable annulus. GST has identified and calculated in a very short time several possibilities for several operators regarding the effects on possible production volumes, the power consumption of the ESP and the investment costs. |